Against the backdrop of continuous upgrading of industrial assembly technology, bolt over-yield tightening technology has been increasingly widely applied in the assembly of critical components in automotive and other industries, thanks to its characteristics of high preload and strong stability. This technology, with the torque-angle method at its core, tightens bolts into the plastic zone above the yield point but below the fracture range, utilizing the material strain hardening effect to upgrade fastening performance, becoming an important solution for threaded fastening in the manufacturing field. This article will analyze the core logic of bolt over-yield tightening technology, and provide a detailed review of its application advantages and limitations to serve as reference for process selection.

I. Core Essence of Bolt Over-Yield Tightening Technology

Bolt over-yield tightening is not simply overtightening, but rather a refined assembly process based on material mechanics. The core is to controllably tighten bolts into the plastic zone and utilize strain hardening characteristics to achieve dual improvements in bolt performance and fastening effects.

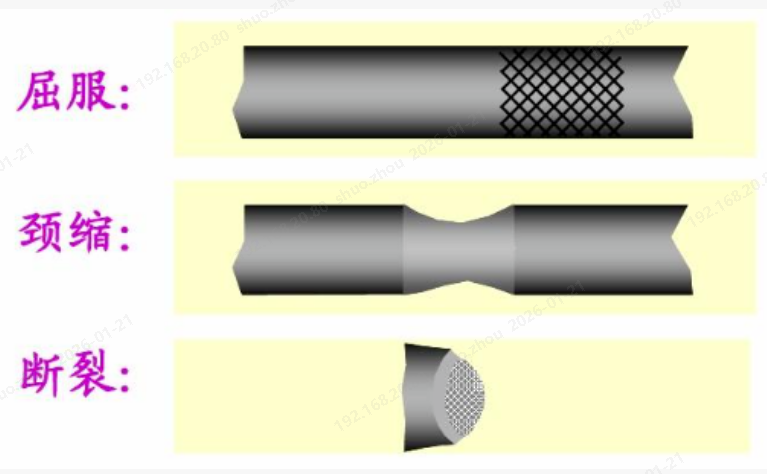

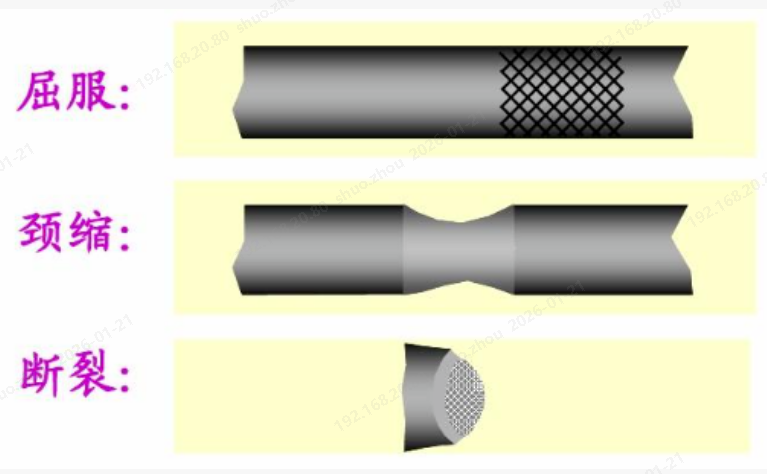

During the tightening process, the shear stress in the bolt will be greatly reduced after the operation is completed, retaining only axial normal stress, allowing the bolt to withstand external loads at a higher yield strength state. Meanwhile, carbon steel and alloy steel bolts have a uniform plastic zone of 5%-15% after the yield point. By strictly controlling the tightening angle and limiting the total bolt elongation to 2%-4%, the risks of necking and fracture can be effectively avoided. The strain hardening effect produced when the bolt enters the plastic zone can significantly increase its yield strength, forming a "cold-work hardened" state that substantially enhances connection stability and reliability.

II. Core Advantages of Bolt Over-Yield Tightening Strategy

(1) High Preload and Good Stability

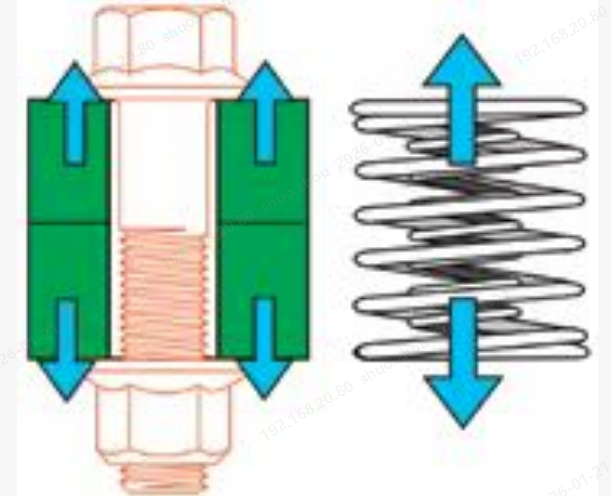

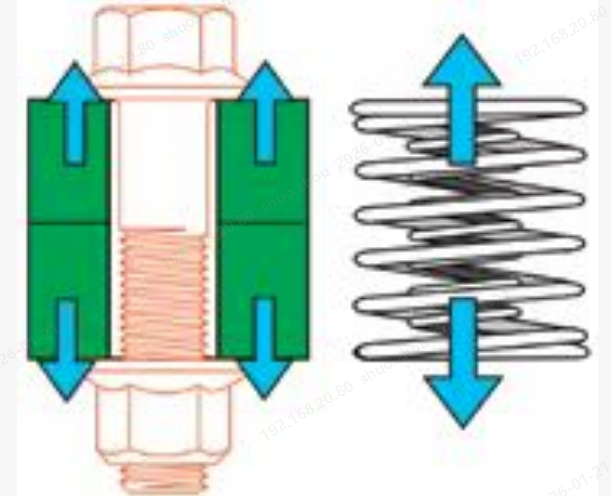

After the bolt passes the yield point and enters the strain hardening stage, the axial force can increase by 30%-50% compared to traditional processes. The preload is less affected by factors such as lubrication and surface roughness, depending only on bolt strength. The preload scatter of the same batch of connections can be controlled within approximately ±10%, which is better than the ±25%-30% of the traditional torque method, significantly improving fastening precision.

(2) Outstanding Anti-Loosening and Anti-Fatigue Performance

Higher thread flank contact pressure raises the threshold for micro-vibration slip, effectively reducing axial force attenuation under high temperature and alternating loads. Meanwhile, the uniform plastic deformation of the bolt forms favorable residual compressive stress at the thread root, delaying fatigue crack initiation and increasing bolt service life by 20%-40% compared to elastic range tightening processes.

(3) Maximizing Material Utilization

The bolt cross-sectional area is fully utilized. Under the premise of ensuring unchanged clamping force, the bolt diameter can be appropriately reduced or the strength grade lowered, with single bolt weight decreasing by 10%-20%. For critical components such as automotive chassis and engine cylinder heads, this can achieve significant material savings and cost reduction effects.

(4) Stable and Reliable Long-Term Clamping Force

After plastic deformation is completed, the bolt is in a cold-work hardened state with creep and stress relaxation rates far lower than bolts tightened in the elastic range. Stable clamping force can be maintained even under harsh conditions such as high temperature and thermal cycling, ensuring long-term connection reliability.

III. Application Limitations of Bolt Over-Yield Tightening Strategy

(1) Bolts Are Single-Use Components

Bolts produce permanent plastic deformation after over-yield tightening. The threads cannot return to the original yield point after disassembly, and re-tightening cannot guarantee fastening effects. Reuse significantly increases fracture risk; replacement with new parts is recommended.

(2) Strict Requirements for Connected Part Consistency

If the connection pair has issues such as stiffness differences, large gaps, or poor flatness, it will cause excessive fluctuations in assembly angles, making it difficult to design suitable process parameters. Even adjusting the threshold torque will weaken the technical advantages of this process. Such scenarios are more suitable for the traditional torque method.

(3) Higher Process and Equipment Investment Costs

Compared to the traditional torque method, the process parameter design for over-yield tightening is more complex, requiring extensive assembly trials to verify the rationality of torque and angle. Meanwhile, tightening equipment needs to be equipped with high-resolution sensors and servo devices, resulting in higher procurement costs, and subsequent debugging and maintenance are also more complicated.

(4) Clear Limitations in Application Scenarios

Soft connections, short threaded areas where bolt grip length is less than 1 times bolt diameter, components requiring repeated disassembly for maintenance, and connections with low-strength parent materials such as aluminum alloy and magnesium alloy are not recommended for this process, as this may easily lead to fastening failure or parent material damage.

Conclusion:

Bolt over-yield tightening technology, with its characteristics of high preload, strong stability, and excellent anti-fatigue performance, can fully utilize bolt performance while achieving material savings and cost reduction. It is a common assembly solution for key rigid connection parts such as automotive chassis and engine cylinder heads. However, this technology also has issues such as single-use requirements, high demands on processes and equipment, and limited application scenarios. In actual production, comprehensive judgment must be made based on the characteristics of connected parts, operating conditions, and cost budgets, with reasonable matching of tightening processes to fully leverage its technical value.