Automatic Screw Tightening Machines vs Manual Screwing: A Comprehensive Competition of Efficiency, Yield Rate, and Cost

In the wave of intelligent transformation in manufacturing, the optimization of every production process directly relates to a company's core competitiveness. Screw fastening, as a fundamental process in product assembly, profoundly affects product performance, production capacity, and overall cost. Traditional manual screwing methods once dominated the market due to low entry barriers and small initial investment, but with the surge in demand for high-volume, high-precision production, automatic screwing machines have gradually become core equipment for industry upgrading. This article will comprehensively analyze the differences between automatic screwing machines and manual screwing from three core dimensions: efficiency, yield rate, and cost.

I. Efficiency Showdown: Automatic Screwing Machines Break Through Human Physiological Limits

In manufacturing production scenarios, efficiency directly determines production capacity, and the difference in screw fastening efficiency will be infinitely magnified in high-volume production settings. The upper limit of manual screwing efficiency is constrained by human physiological limits, while automatic screwing machines achieve a qualitative leap in efficiency through automated operations.

From the perspective of effective working time, manual screwing has inherent shortcomings. A worker's standard working time is typically 8 hours per day, but the actual effective working time is less than 6 hours, as time must be allocated for breaks, drinking water, restroom use, and other physiological needs. More critically, screw fastening is extremely repetitive labor. Prolonged operations cause severe fatigue in workers. As fatigue accumulates, the operating speed gradually slows down, and the error rate increases, further compressing effective working time. In contrast, automatic screwing machines are completely free from human physiological limitations and can operate 7×24 hours without interruption, requiring no rest or state adjustments, with effective working time accounting for nearly 100%. Whether during normal daytime production hours or nighttime off-peak hours, automatic screwing machines can maintain a stable operating rhythm, providing core support for companies to increase production capacity.

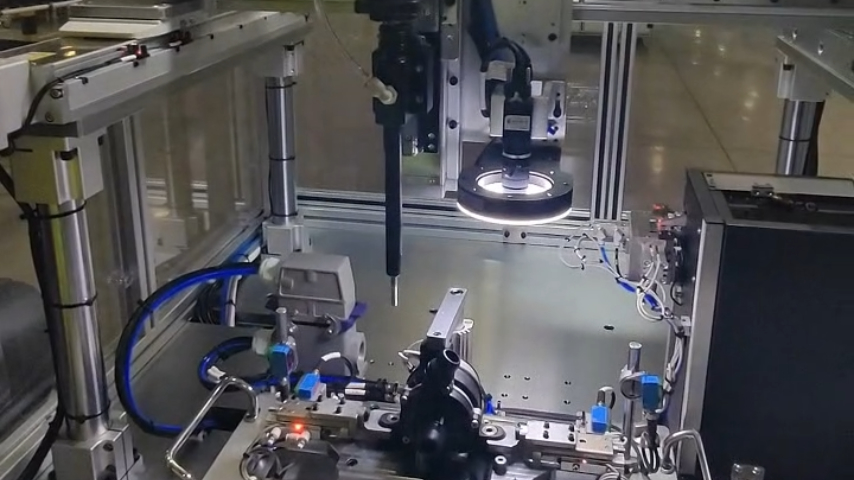

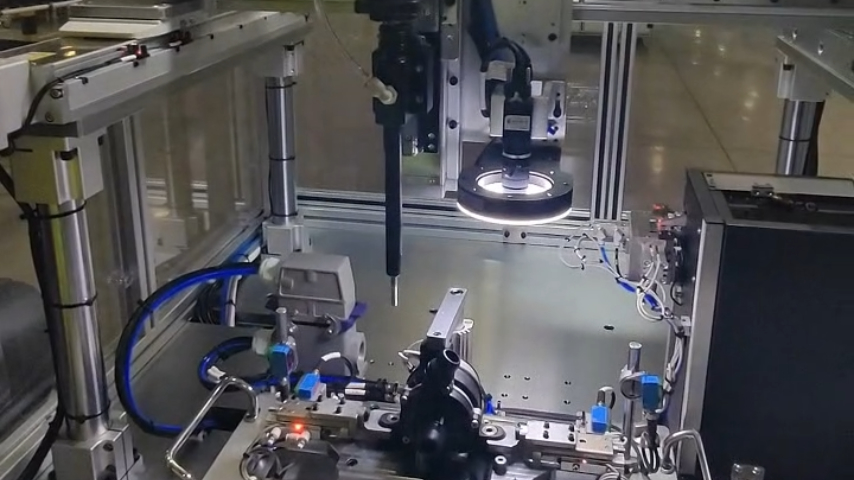

In complex workstation operation scenarios, the efficiency advantage of automatic screwing machines is even more prominent. For concealed screws inside certain products or multi-angle screws, manual operation requires constant posture adjustments or even the use of auxiliary tools, resulting in low efficiency. Automatic screwing machines can be customized with multi-axis tightening mechanisms according to workstation requirements, enabling simultaneous fastening of multiple screws or performing operations in concealed workstations deep inside products without the need to adjust equipment position. Additionally, automatic screwing machines can be integrated with other equipment on the production line and incorporated into automated production lines, reducing waiting time during process handovers and further improving overall production efficiency.

II. Yield Rate Control: Automatic Screwing Machines Fortify Quality Defense

Product yield rate is the lifeline of manufacturing. The quality of screw fastening directly affects product service life, safety performance, and market reputation. The quality stability of manual screwing is subject to various subjective factors and has significant fluctuations, while automatic screwing machines elevate yield rates to new heights through accurate torque control and anomaly monitoring capabilities.

Torque precision is the core indicator of screw fastening quality. When workers operate using electric or pneumatic screwdrivers, the torque size completely depends on personal experience and feel. Even skilled workers cannot guarantee that every screw receives exactly the same torque, and abnormalities such as stripped threads or floating locks are difficult to detect promptly. Automatic screwing machines are equipped with high-precision torque sensors and closed-loop control systems that can collect torque data in real-time during the tightening process and automatically adjust tightening force according to preset torque parameters, ensuring torque error for each screw is controlled within ±5%. Whether for tiny electronic component screws or large mechanical equipment fastening screws, automatic screwing machines can achieve accurate torque control, fundamentally ensuring consistency in fastening quality. Furthermore, automatic screwing machines also have anomaly identification functions. During the tightening process, once abnormal torque, abnormal speed, abnormal tightening stroke, or other conditions are detected, the machine will immediately stop operation and issue an alarm signal to prevent defective products from flowing into the next process. The screw feeder can also be equipped with a length detection function to automatically remove incorrect screws and prevent the misuse of screws.

III. Cost Accounting: Automatic Screwing Machines Demonstrate Significant Long-term Advantages

When companies select production equipment, cost is one of the core considerations. Although the initial procurement cost of automatic screwing machines is higher than manual screwing, from a long-term operation perspective, this cost difference rapidly narrows in high-volume production scenarios because a single automatic screwing machine can replace multiple workers, significantly reducing labor costs. At the same time, worker turnover is relatively high, requiring companies to continuously recruit new employees and conduct training, further increasing hidden costs. In contrast, the operating costs of automatic screwing machines mainly include equipment maintenance, energy consumption, and consumables replacement, with relatively low maintenance costs. Additionally, the reduction in material waste brought by high yield rates further reduces the comprehensive cost of automatic screwing machines. In the manual screwing process, material waste such as screw damage and workpiece scrapping caused by operational errors is relatively serious. For companies with high-volume production, the cost savings brought by this difference are considerable, and the reduction in rework labor hours and material waste for defective products further lowers overall production costs.

Based on the above analysis, automatic screwing machines are superior to manual screwing in terms of efficiency, yield rate, and long-term cost, but they are not suitable for all companies. A comprehensive consideration must be made based on actual conditions such as production scale, product precision requirements, and financial situation. For high-volume, high-precision, standardized production scenarios, automatic screwing machines are the inevitable choice; for low-volume, multi-variety, non-standardized production scenarios, if product screw specifications are diverse, fastening workstations are complex, and funds are limited, manual screwing can be temporarily adopted. However, as production scale expands, automatic screwing machines should be gradually introduced to improve production levels.