In industrial fields such as automotive assembly and machinery manufacturing, threaded fastening is a widely used basic connection method. The application of processes such as the torque method and torque-plus-angle method has made preload control in threaded fastening increasingly accurate. In conventional bolt-and-nut connection structures, there are two operation methods: fixing the bolt head and tightening the nut and holding the nut and tightening the bolt. Although these two methods appear to differ only in the operation target, they actually show significant differences in multiple dimensions including process specifications, force performance, and practical implementation. Choosing the appropriate tightening method is key to ensuring fastening effectiveness and improving equipment connection reliability.

I. Standards and Conventional Applications: No Mandatory Requirements, Prefer Nut Tightening

Currently, there are no explicit national standards or industry specifications within the industry that mandate the use of either bolt tightening or nut tightening exclusively for bolt-and-nut connections. From a design principles perspective, both tightening methods are feasible.

In long-term production practice, nut tightening has become the mainstream choice for conventional bolt-and-nut connections due to its operational stability and universality, and it is the general operating method used at assembly sites across various industries. Only at special fastening locations where tightening equipment cannot access or where space conditions are limited is the bolt tightening method selected to complete assembly.

II. Stress States: Theoretically Consistent, but Deviations Occur Due to Structural Differences in Practice

(A) Theoretical Level: No Essential Difference in Bolt Stress

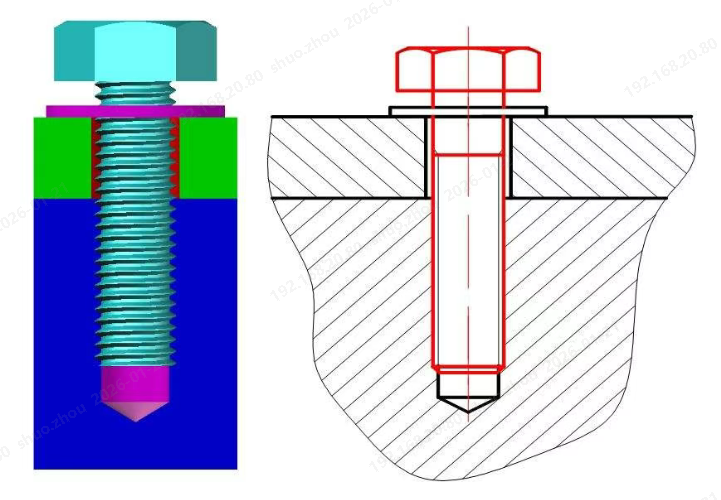

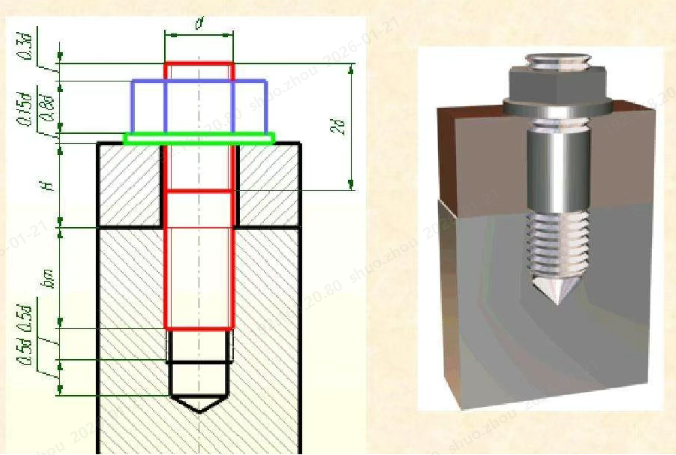

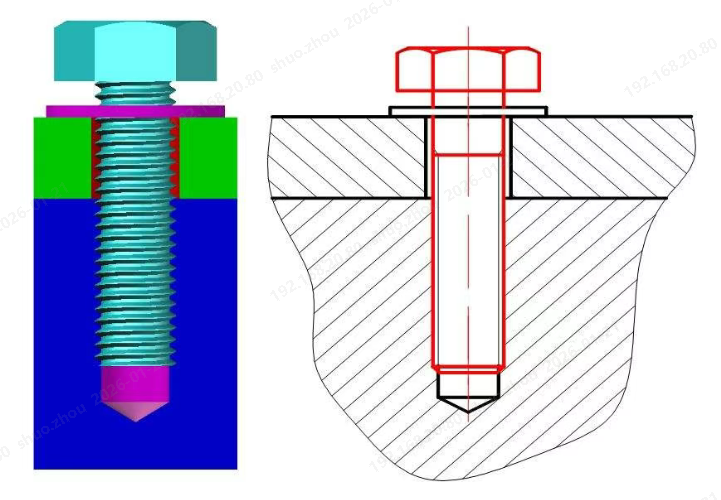

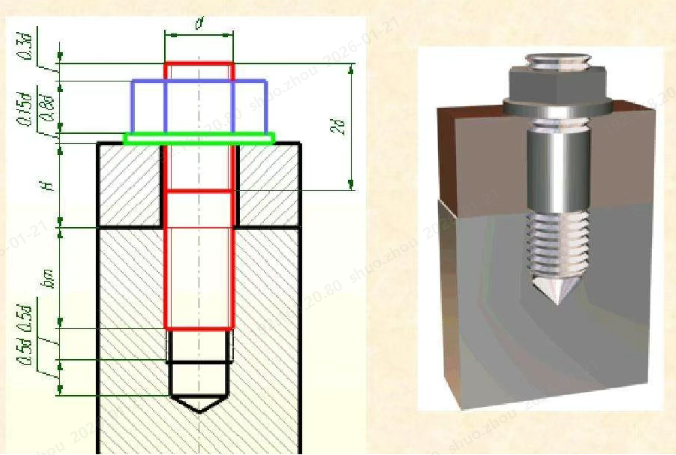

From a mechanical principles analysis, whether tightening the bolt or the nut, the bolt body simultaneously withstands two core stresses: tensile stress caused by preload and torsional shear stress applied by thread torque. If the friction coefficient between the bolt and nut remains consistent and the support surface diameters match perfectly, the combined stress on the bolt will not show significant deviations, and theoretically, the same fastening effect can be achieved.

(B) Practical Level: Structural Differences Lead to Stress and Torque Deviations

In actual assembly, the stress effects of the two methods are prone to gaps, with the core cause being the structural details and dimensional matching issues between bolts and nuts.

Inconsistent Friction Coefficients: The included angle dimensions of the bolt head support surface and nut support surface often have design deviations, directly resulting in difficulty maintaining uniform friction coefficients between the two, thereby changing the friction torque during tightening and causing obvious fluctuations in the combined stress on the bolt.

Unreasonable Dimensional Matching: If attention is not paid to the compatibility between bolts and nuts during design, such as selecting different national standard series for flange bolts and flange nuts, this will cause mismatch between the support surface diameters of the two. Differences in equivalent friction diameter will further affect torque transmission efficiency, significantly reducing the precision of preload control. Therefore, in the design phase, priority should be given to selecting matching products with consistent bolt and nut support surface diameters to reduce fastening deviations at the source.

III. Practical Implementation: Significant Differences in Space, Tools, and Operations

The two tightening methods show significant differences in operational convenience, space requirements, and tool adaptability during actual assembly, directly affecting production efficiency and assembly difficulty. These are also important considerations for on-site selection of tightening methods.

(A) Space Utilization and Bolt Insertion: Nut Tightening Has Greater Operational Advantages

The method of inserting the bolt from the outside and tightening the nut from the inside is more convenient to operate. It only requires reserving space for the nut thickness, bolt protrusion length, and a small amount of anti-rotation tooling to meet assembly needs. If inserting the bolt from the inside and then tightening, not only is the alignment of bolt holes more difficult, but it also requires larger operating space, imposing more stringent requirements on space conditions at the assembly site.

(B) Tool Adaptability: Each Has Its Characteristics, with Little Difference in Comprehensive Cost

When tightening the bolt, short sockets can be selected directly, offering stronger tool adaptability without needing to consider bolt protrusion length. When tightening the nut, sockets must be selected based on bolt protrusion length. Some bolts with guide functions have longer protrusions and require the use of long sockets, which not only increases tool procurement costs but may also reduce socket rigidity.

However, in actual production, the design of anti-rotation tooling will use long sockets on the other end, so the comprehensive costs of tool selection for both methods do not differ significantly. Tool factors are not the core basis for selecting tightening methods.

(C) Operational Loss: Bolt Tightening Easily Produces Additional Friction Torque

Bolt tightening has an easily overlooked issue—additional friction loss caused by assembly alignment. If the bolt assembly has slight misalignment, during the tightening process, the bolt shank will generate additional friction with the bolt hole, directly increasing friction torque and forcing the actual input torque to increase. In contrast, nut tightening operations are basically unaffected by bolt alignment issues and do not need to bear this additional torque loss.

IV. Special Industries: Significant Torque Requirements Differences, with Higher Torque Requirements for Bolt Tightening

The torque differences between the two tightening methods are more prominent in special industries, with the aviation industry as an example: the nominal torque requirements for bolt tightening in the aviation industry are approximately 10% higher than those for nut tightening.

In addition to being affected by the friction deviations and additional torque losses from assembly alignment mentioned above, this difference is also related to special designs in the aviation industry. Aviation bolts often adopt interference fit processes, and the bolt support surface diameter is relatively small. These factors further amplify the torque requirement gap between the two tightening methods.

Conclusion

Bolt tightening and nut tightening are not simply operational choices, but require comprehensive judgment based on assembly space, tool compatibility, part structural dimensions, and industry process requirements.

In conventional assembly scenarios, tightening the nut is more likely to ensure fastening stability and is the better choice. In special space-limited areas where tightening equipment cannot access, bolt tightening is a more practical solution. As long as basic work such as bolt alignment adjustment, friction coefficient matching, and dimensional design is done well, both tightening methods can achieve the same clamping force and fastening effect, effectively avoiding impacts on equipment connection reliability due to improper method selection.