In the field of mechanical assembly, bolted connections serve as the most fundamental and critical joining method. The quality of fastening directly determines the operational stability, safety, and service life of equipment. However, approximately 90% of the torque during the bolt tightening process is consumed in overcoming frictional resistance. This characteristic means that even minor fluctuations in the friction coefficient can cause significant deviations in the final clamping force, thereby creating potential hidden dangers of equipment failure. To address this issue, the "Torque and Angle" composite control strategy of electric torque screwdrivers can effectively reduce the impact of friction coefficient fluctuations on clamping force, providing reliable assurance for high-precision assembly.

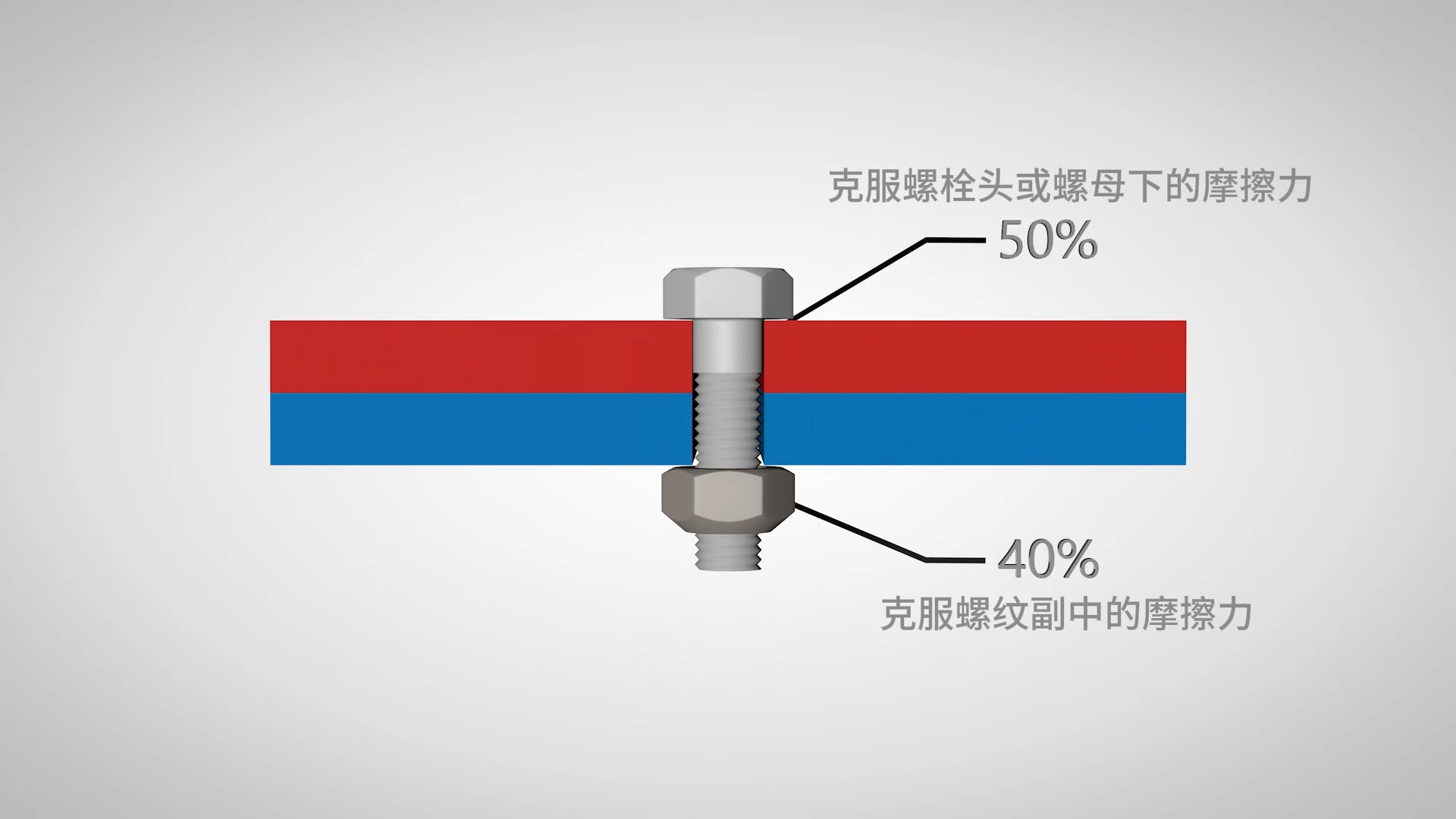

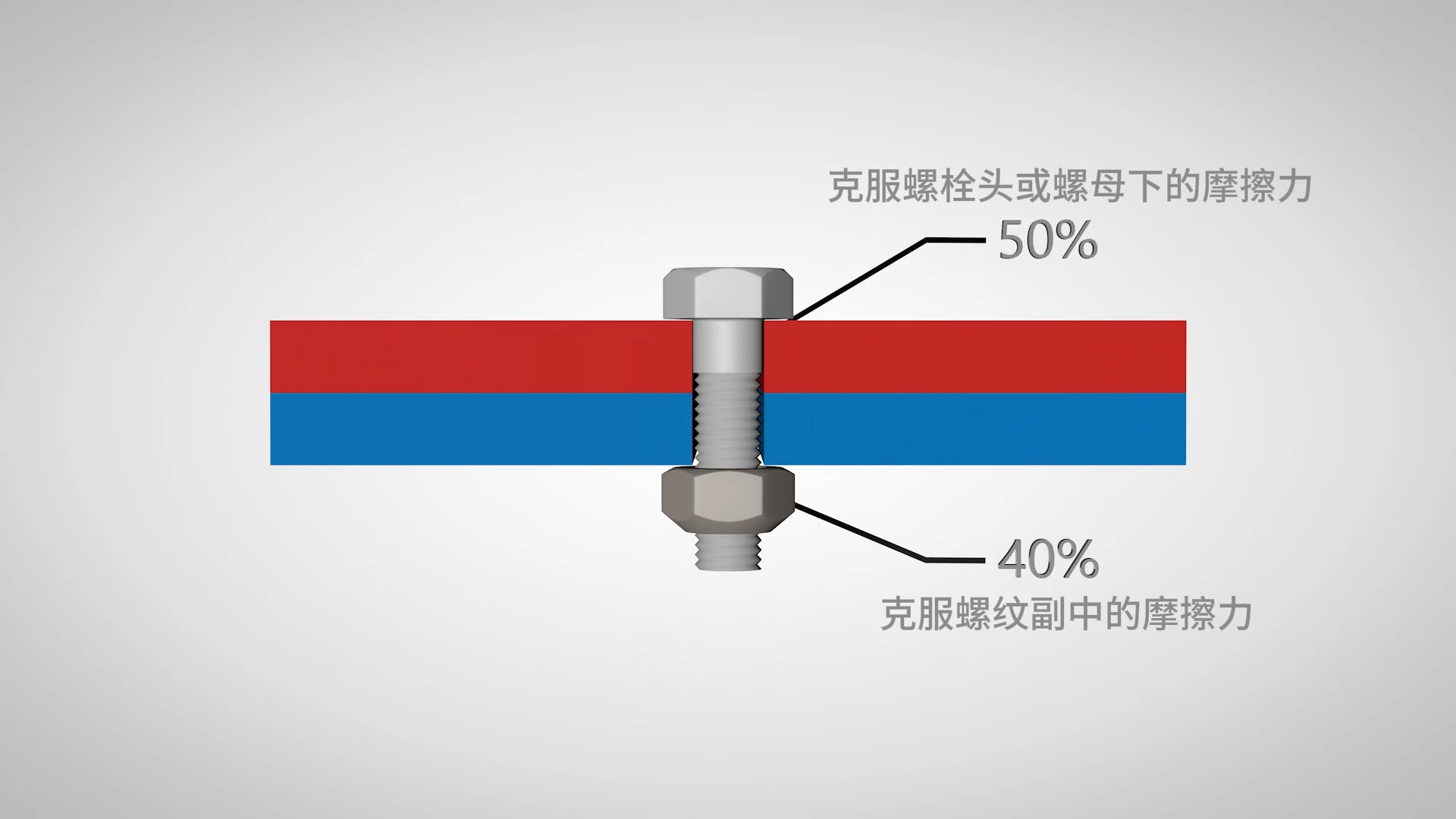

To understand the effect of friction coefficient fluctuations on bolt clamping force, it is first necessary to understand the mechanical principles of bolt tightening. The bolt tightening process essentially involves converting the torque output from the electric torque screwdriver into bolt preload, thereby generating reliable clamping force between workpieces to form a stable connection structure. However, in actual operation, the vast majority of torque is used to overcome friction, including friction between threads and end-face friction between the bolt head and workpiece contact surface. These two friction components account for as high as 90% of the torque consumption, with only about 10% of torque being truly converted into clamping force. The friction coefficient is influenced by multiple factors, such as thread and end-face machining accuracy, surface roughness, lubrication conditions, material compatibility, etc. Subtle changes in these factors can lead to fluctuations in the friction coefficient, causing significant deviations in clamping force under the same input torque, which fails to meet high-precision assembly requirements. The "Torque and Angle" composite control strategy of electric torque screwdrivers achieves dynamic adjustment and abnormal alarming by simultaneously monitoring two core parameters—torque and rotation angle—and comparing them with preset thresholds.

I. High-Friction Scenarios: Angle Compensation Mechanism of Electric Torque Screwdrivers

In high-friction coefficient scenarios, due to increased friction resistance between threads and end faces, the situation of "torque meets standards but angle not" (torque reaches preset threshold but rotation angle does not reach corresponding stroke) easily occurs. In this case, the actual clamping force is often insufficient. To address this problem, the composite control strategy of electric torque screwdrivers activates the angle compensation mechanism: when torque reaches the preset value first, the electric torque screwdriver will not stop immediately but continue driving the bolt to rotate until the rotation angle reaches the preset angle threshold. During this process, the electric torque screwdriver continuously monitors torque changes in real-time. If torque exceeds the safety upper limit due to further increased friction resistance, the electric torque screwdriver will immediately trigger the alarm mechanism and stop, preventing bolt deformation, fracture, or damage to connected parts due to overload. This ensures both meet standards clamping force and safety during the tightening process.

II. Low-Friction Scenarios: Torque Compensation Mechanism of Electric Torque Screwdrivers

In low-friction coefficient scenarios, where friction resistance is smaller and bolt rotation resistance is low, the situation of "angle meets standards but torque not" (bolt rotation angle reaches preset stroke but torque output from the electric torque screwdriver has not yet reached the preset value) easily occurs. In this case, the clamping force also fails to meet requirements. For this operating condition, the composite control strategy of electric torque screwdrivers activates the torque compensation mechanism: when the angle reaches the preset value first, the electric torque screwdriver will not stop working but continue maintaining power output until torque reaches the preset threshold. Only after ensuring that both torque and angle fall within safe threshold ranges will the tightening action be completed and the machine stop. This dual meeting standards mechanism fundamentally avoids the limitations of single-parameter control. Through collaborative monitoring and dynamic compensation of these two core parameters by the electric torque screwdriver, the negative impact brought by friction coefficient fluctuations is effectively offset, keeping the clamping force consistently stable within a reasonable range.