In industrial assembly sites, "whether the bolt is tightened properly" has always been a key focus of quality control. Many people subconsciously believe that: the tighter the bolt is tightened, the more reliable the connection will be. But is this really true? The answer is no.

In modern manufacturing, both over-tightening and insufficient tightening are assembly hazards. Only scientific and controllable tightening methods can truly ensure connection reliability.

I. The Essence of Bolt Tightening: Clamping Force, Not "Feel"

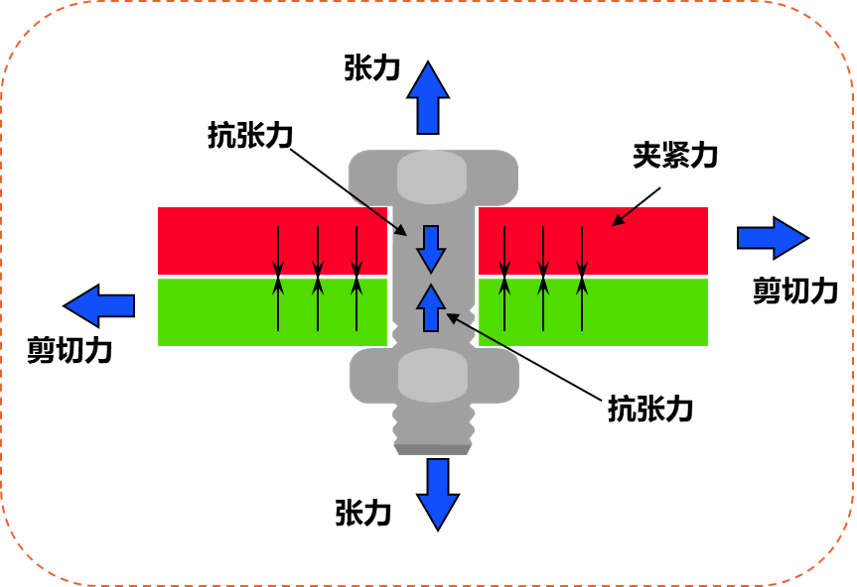

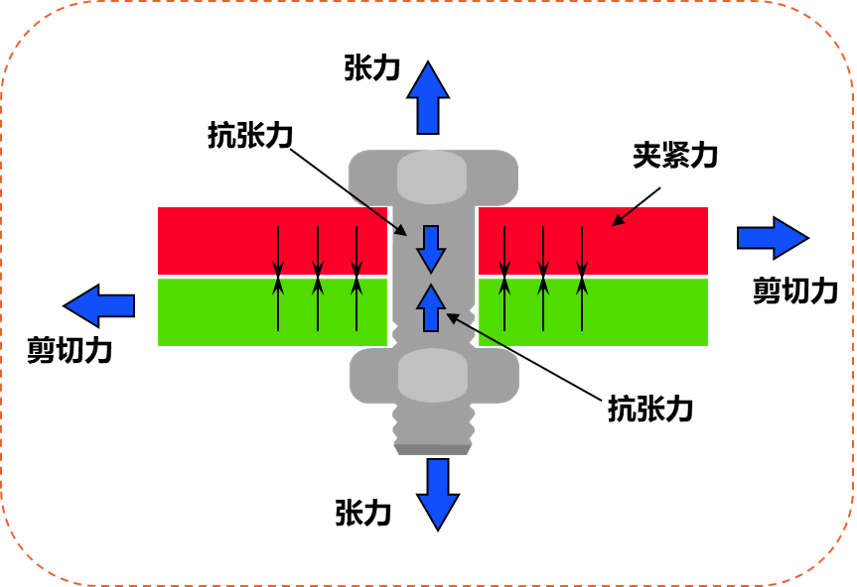

The purpose of bolt tightening is not simply to tighten the threads "all the way," but to generate axial tension (preload) within the bolt through tightening torque, thereby providing stable clamping force to the connected parts.

During the tightening process, the bolt undergoes elastic deformation: within the elastic range, the bolt can spring back and the connection remains stable and reliable. Clamping force has a reasonable proportional relationship with torque. However, once tightening force continues to increase and the stress value exceeds the bolt's yield strength, the bolt will produce irreversible plastic deformation and may also damage the workpiece.

II. What Problems Can Occur When Bolts Are Tightened Too Much?

When tightening stress exceeds the bolt's yield strength, the bolt will undergo irreversible plastic deformation. Common risks include:

Bolt stretching and thinning, resulting in reduced strength

Thread seizing or stripping, making later disassembly impossible

Deformation or cracking of connected parts (such as aluminum parts)

Bolt fracture during long-term use

These situations where the bolt appears to be "tightened very tightly" actually lay hidden dangers for subsequent failures.

III. Insufficient Tightening Cannot Be Ignored Either

Contrary to over-tightening, insufficient tightening also seriously affects assembly quality:

Insufficient clamping force, causing workpieces to loosen during vibration

Safety hazards in critical structural components

Therefore, tightening is not about being "as tight as possible," but rather requires being "just right."

IV. What Factors Affect Tightening Torque?

Bolt and Fastener Themselves: This is the most fundamental but also most easily overlooked category of factors.

Thread specifications and precision: Different pitches and thread angles require different torques

Material and strength grade: High-strength bolts allow greater torque; different material hardness results in obvious friction coefficient variations

Surface treatment methods: Different coatings have very different friction coefficients

Friction Coefficient Related Factors: 90% of torque is consumed by friction; only 10% of torque is converted into clamping force

Thread surface roughness, presence of impurities, burrs, or damage

Lubricating oil under bolt head

Connected Parts Factors: The material and surface of connected parts also affect tightening torque

Material rigidity (hard joint/soft joint): Hard joints show rapid torque rise prone to overshoot; soft joints have large angles prone to torque decay

Presence of inclusions: Oil contamination, foreign objects, and burrs all affect torque

Tightening Process and Strategy Factors: Selected tightening strategies and speeds also affect final torque

Tightening Tools and Equipment Factors: Tool type selection, tool precision, and calibration status also affect tightening torque

V. Danikor Intelligent Tightening Tools: Making Bolt Tightening Controllable and Traceable

Compared to traditional clutch-type tools or empirical manual tightening, Danikor's intelligent tightening tools have significant advantages in tightening quality control:

Built-in high-precision torque sensors monitor the tightening process in real time. With self-developed high-precision algorithm control, within the full torque range, the standard deviation accuracy is 6σ±5%, CMK>1.67.

Closed-loop control system dynamically adjusts output based on feedback. Throughout the entire tightening process, data such as slope, torque, angle, and steps are recorded and monitored in real time, uploaded to the Web interface in real time, and can interface with enterprise MES systems to achieve interconnection of production data.

Multi-strategy tightening, featuring various advanced tightening strategies such as clamping torque and yield point, ensuring every screw reaches optimal fastening condition.

More comprehensive intelligent error-proofing, through superimposed judgment using both sensors and current, ensures qualified torque. With one-click activation, monitoring modes for floating height, thread stripping, and repeated tightening issues can be enabled, ensuring timely feedback of tightening abnormalities.

Bolts are not better when tightened tighter, but are best when tightened scientifically.

Only through reasonable selection, precise torque control, and intelligent tightening tools working together can bolts provide stable and reliable clamping force, avoid hidden dangers brought by over-tightening, and truly ensure product quality and usage safety.