In the field of mechanical manufacturing and assembly, bolt tightening is a fundamental process that maintains product structural stability, while tightening data serves as a crucial basis for measuring tightening quality and ensuring product safety. Although tightening operations may seem simple, they are directly linked to the reliability of the product throughout its entire lifecycle. This is especially critical in industries such as automotive and aerospace, where assembly precision requirements are extremely stringent—every set of tightening data carries the important mission of quality traceability. With the development of intelligent manufacturing, the popularization of intelligent tightening tools has made the collection, recording, and analysis of tightening data more convenient, allowing the full value of tightening data to be realized. Understanding the importance of tightening data and mastering its application logic is of great significance for improving manufacturing and assembly quality.

Tightening data acts as a "traceable certificate" for product quality, which is one of its core values. In traditional assembly modes, tightening operations often rely on manual experience, lacking effective records of key parameters such as torque and angle. Once a product experiences fastener-related failures later on, it becomes difficult to identify the root cause of the problem, which not only increases maintenance costs but may also damage brand reputation. Complete tightening data records can clearly present the tightening process of every single bolt—including tightening torque value, tightening angle, rotation speed, operation time, operator, and corresponding workstation information. This data is like the "fingerprint" of product quality, possessing unique characteristics and being non-replicable. When product abnormalities occur, these data enable rapid traceability to specific processes for problem investigation, providing a reliable basis for fault resolution.

1. Tightening Data: The Key to Achieving Transparent Management of Assembly Processes

One of the core functions of tightening data is to make the originally invisible assembly process transparent, manageable, and analyzable. This can be specifically divided into the following two aspects:

1.1 Controlling Operational Consistency and Reducing Assembly Errors

In large-scale manufacturing scenarios, assembly processes involve a large number of bolt tightening operations. Manual operations inevitably have variations, and without data support, it is difficult to control the consistency of each operation. By recording tightening data, management personnel can monitor the tightening status at each workstation in real-time, understanding whether the tightening parameters of every bolt meet standard requirements. Once abnormal situations such as parameter exceedance or incomplete tightening occur, the system can issue timely alerts, enabling staff to handle issues promptly and prevent non-conforming products from entering the next process. This transparent management model can effectively reduce assembly errors and enhance the stability of overall assembly quality.

1.2 Supporting Process Optimization and Improving Assembly Rationality

Accumulated tightening data can also provide data support for assembly process optimization. Through statistical analysis of large amounts of tightening data, common problems in the assembly process can be identified, such as parameter fluctuations occurring with certain bolt models under specific working conditions, or efficiency improvement potential in tightening operations at certain workstations. Based on these data-driven conclusions, technical personnel can adjust assembly processes and optimize tightening parameters in a targeted manner, further improving assembly reliability and rationality.

2. Intelligent Tightening Tools: The Core Carrier for Standardized Collection and Transmission of Tightening Data

The standardized recording of tightening data cannot be achieved without support from professional equipment, and intelligent tightening tools are the core carrier among them. Their role in tightening data management is mainly reflected in two dimensions:

2.1 Real-time Standardized Collection to Avoid Human Error

Compared with traditional tightening tools, intelligent tightening tools not only can apply the set tightening torque but also possess real-time data collection capabilities. During tightening operations, intelligent tightening tools can simultaneously record key parameters such as torque, angle, and rotation speed, avoiding errors and omissions from manual recording and providing standardized foundational data for subsequent data management.

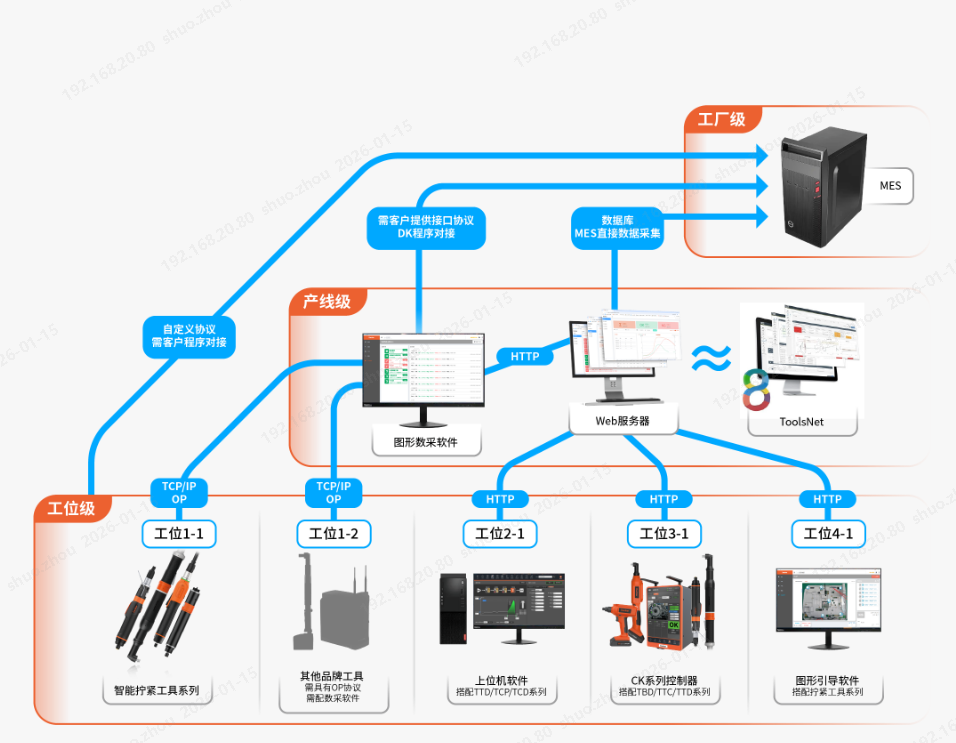

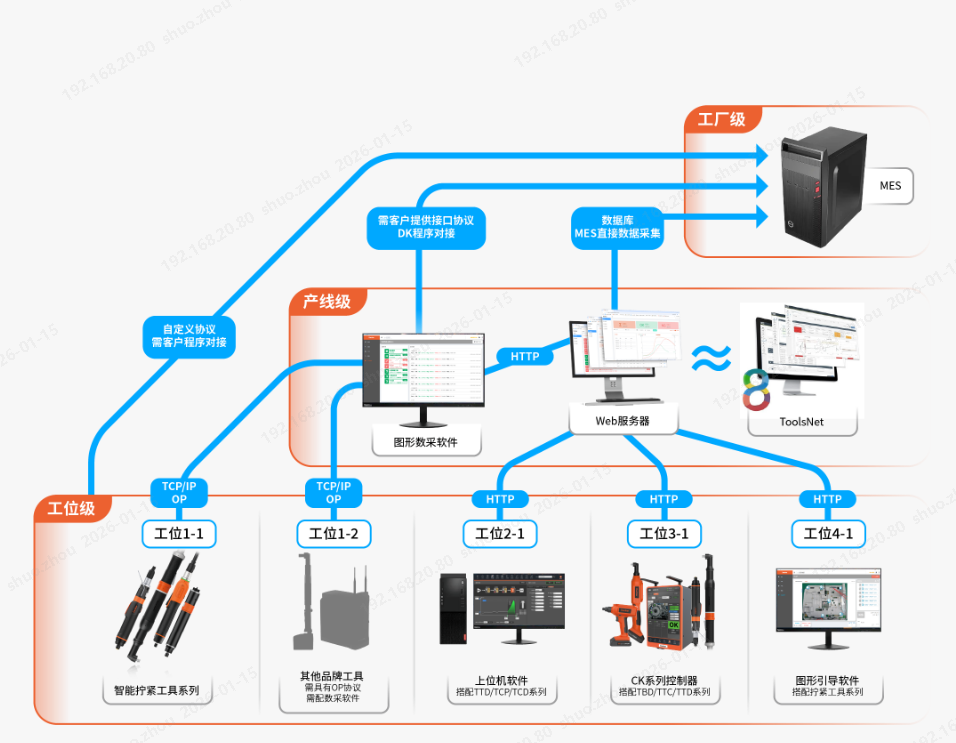

2.2 Real-time Transmission and Integration to Enable Remote Monitoring

Most intelligent tightening tools can integrate with the factory's MES (Manufacturing Execution System), uploading the collected tightening data to the system platform in real-time for centralized management and storage. This real-time transmission and centralized management model makes the application of tightening data more convenient. Management personnel do not need to verify data on-site one by one; they can remotely view tightening data from various workstations through the system, achieving remote monitoring of the assembly process. Additionally, intelligent tightening tools feature data anomaly alarm functions. When tightening parameters exceed preset ranges, the equipment immediately stops operation and issues an alarm, while synchronizing abnormal data to the system to ensure that every tightening operation meets standard requirements, guaranteeing tightening quality from the source.

3. Important Applications of Tightening Data in Different Manufacturing Fields

The importance of tightening data is directly demonstrated in different manufacturing fields. For example, in the automotive manufacturing sector, the bolt tightening of critical components such as engines and chassis directly affects vehicle driving safety. Every critical screw's tightening data must be recorded in detail. Through this data, it can be ensured that the assembly of critical components in each vehicle meets quality standards. If related failures occur subsequently, it enables rapid traceability to specific production batches, workpieces, and operator workstations, providing a basis for maintenance and quality improvement. Furthermore, in other manufacturing fields such as aerospace, engineering machinery, and household appliances, tightening data also plays an important role in ensuring the assembly quality of core components, reducing product failures caused by fastening issues, improving overall product quality stability, and providing data support for production management and process optimization.

Tightening data is an indispensable core for quality assurance in manufacturing and assembly processes. It not only enables transparent management of assembly processes and provides data support for process optimization but also offers reliable basis for product quality traceability. The application of intelligent tightening tools further enhances the standardization of tightening data collection and the timeliness of transmission, allowing the full value of tightening data to be realized. In the current era of increasingly popular intelligent manufacturing, attaching importance to the recording and application of tightening data and rationally matching professional equipment such as intelligent tightening tools has become an important measure to improve manufacturing and assembly quality and ensure product safety.