How Does a Fully Automatic Screwing Machine Achieve Feeding and Tightening of Different Screws Using a Single Screwing Module?

Fully automatic screwdriving machines are increasingly used in manufacturing scenarios such as home appliance assembly and automotive parts production. However, a single product often requires multiple types of screws. If a separate screwing device is configured for each type of screw, it not only significantly increases equipment procurement and maintenance costs but also takes up valuable production line space. Moreover, frequent workstation changes reduce production efficiency. To address this, special structural designs can be used to achieve the goal of "one core module compatible with multiple types of screws." Specifically, depending on the differences in screws, there are two adaptation solutions:

Solution 1: For Screws with the Same Specifications but Different Lengths

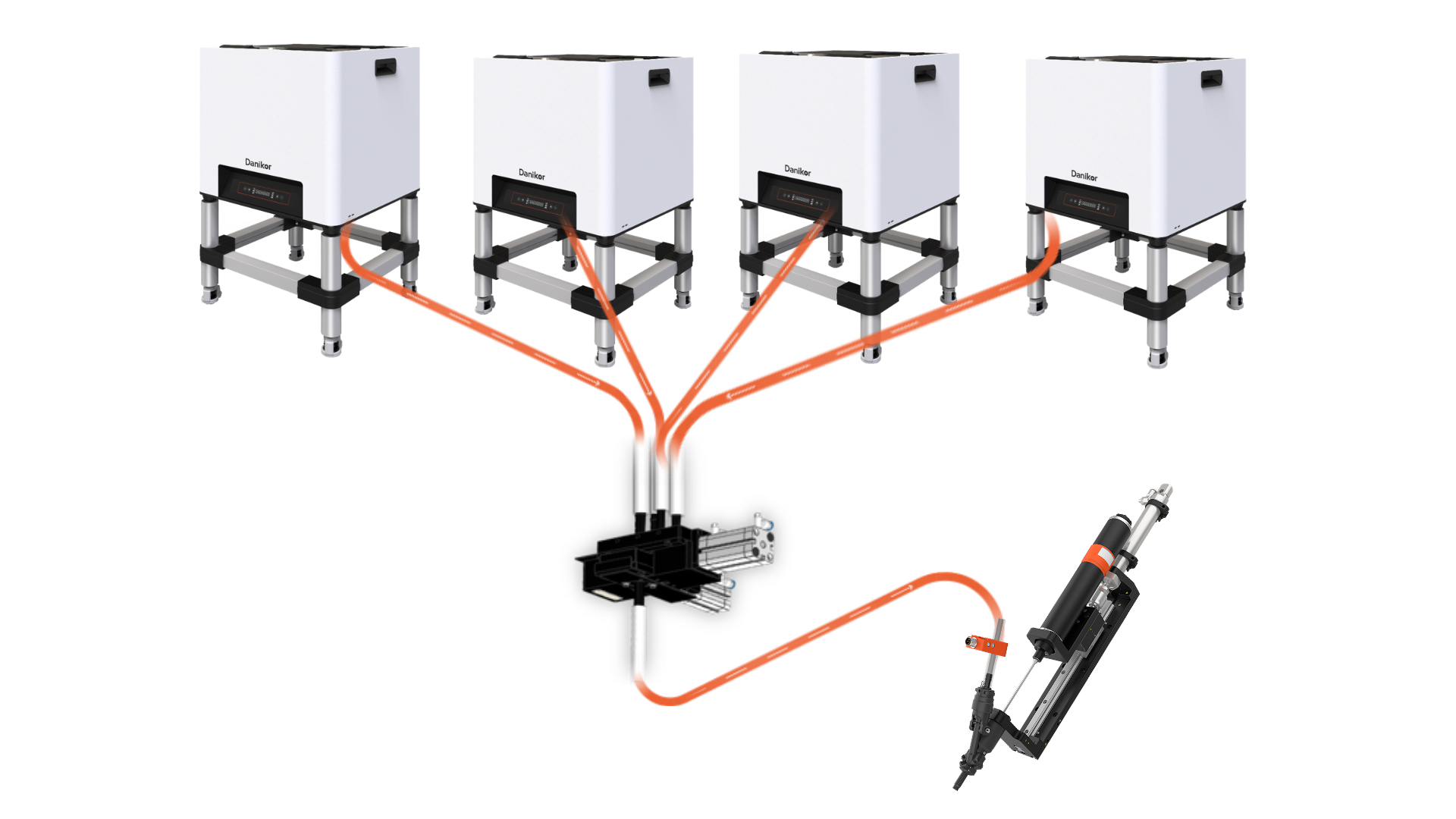

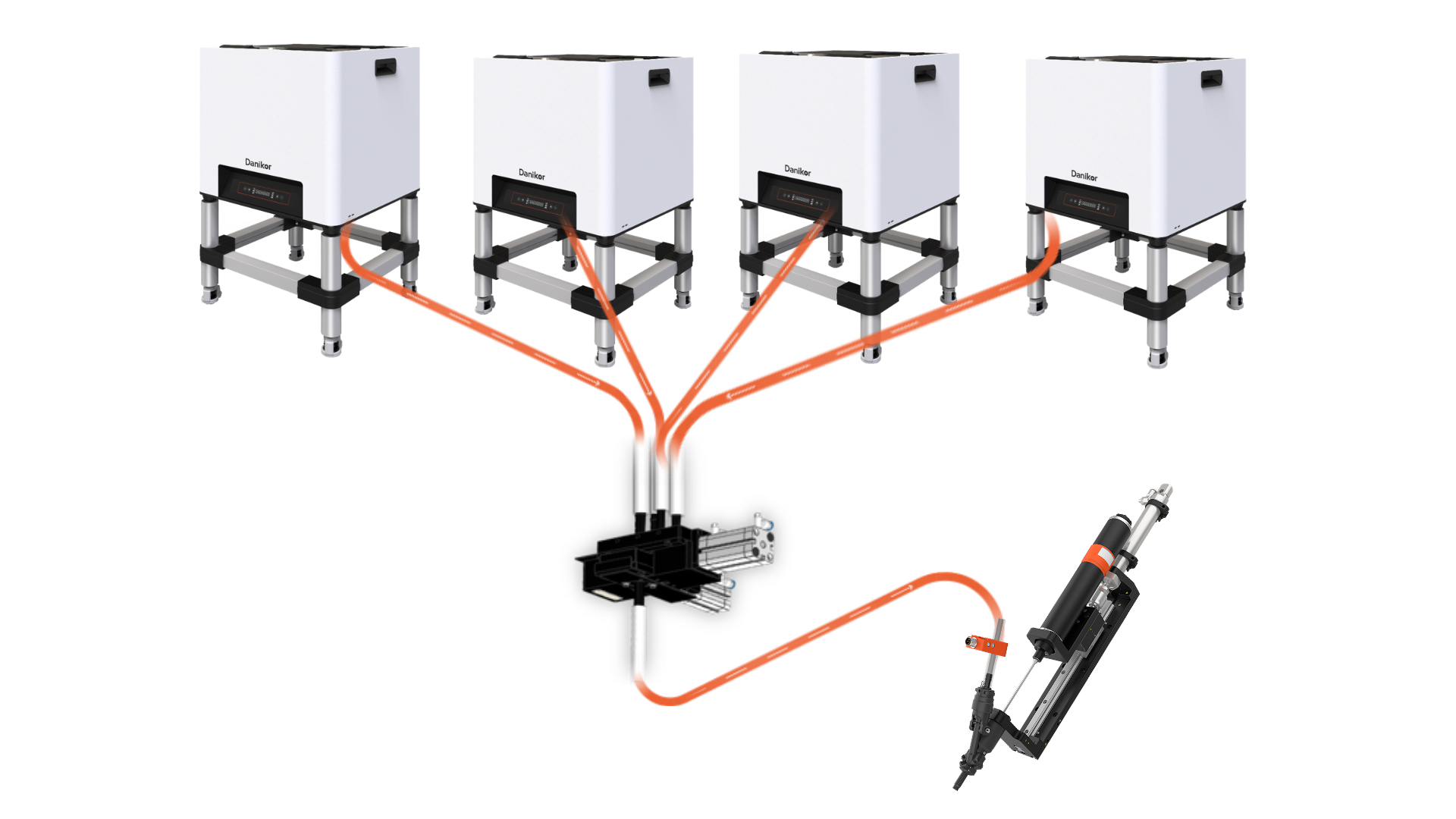

When the screws have the same core specifications such as diameter and pitch, and differ only in length, there is no need to replace the core components of the screwing module. Compatibility can be achieved through "multiple screw feeders supplying materials + channel switching."

Parallel Feeding by Multiple Screw Feeders:

Configure a corresponding number of automatic screw feeders based on the number of different screw lengths. Each feeder is responsible for supplying screws of a specific length, preventing jamming issues caused by mixing screws of different lengths. Each feeder is also equipped with a low-material detection device. When the screw level in the hopper falls below the threshold, an automatic alert is triggered to replenish materials, preventing supply interruption and ensuring accuracy and stability in feeding.

Automatic Switching via Multi-In-One Screw Distributor:

A multi-in-one screw distributor is installed between the screw feeders and the screwing module. The distributor has 2–4 independent inlets (corresponding to different feeders) and one unified outlet (connected to the screwing module). During operation, the PLC control system automatically identifies the required screw length for the current process and sends a signal to the distributor to quickly switch to the corresponding feeding channel. The selected feeder then uses air pressure to accurately deliver the screw to the module’s bit. The entire switching process requires no manual intervention, reducing the risk of incorrect assembly.

Solution 2: For Screws with Significantly Different Specifications

When screws differ significantly in core specifications such as diameter and pitch, and require replacement of core components like the bit and feeding channel, a "mechanical quick-change + auxiliary receiving platform" solution is used to achieve flexible compatibility.

Automatic Bit Replacement via Mechanical Quick-Change Module:

The core components of the screwing module—such as the bit and suction tube—form a mechanical quick-change female connector. When a switch to a different screw specification is needed, the moving mechanism brings the module to a socket selector, where it automatically replaces the female connector with one suited to the next screw. At the same time, the screwing tool automatically switches to the parameters required for the next process.

Auxiliary Receiving Platform to Shorten Screw Pickup Distance:

Since the quick-change module uses vacuum suction to pick up screws, the "screw pickup distance" becomes a key factor affecting the production line cycle. In traditional setups without a receiving platform, the screw feeder is usually fixed beside the production line, and the screwing module must travel from the screwing workstation to the feeder outlet to pick up a screw, resulting in a long round-trip distance and time. By installing a receiving platform adjacent to the screwing workstation, the pickup distance is significantly reduced, speeding up the production cycle.

Conclusion

Through the above two solutions, a single screwing module can handle the screwing needs of multiple types of screws for the same product. Compared to the traditional "one screw, one device" model, this approach reduces equipment procurement costs, saves production line space, and minimizes downtime caused by workstation switching. It also enhances production line flexibility. When new screw specifications are introduced in the future, there is no need to restructure the production line—Solution 1 only requires adding one screw feeder, and Solution 2 only requires purchasing the corresponding quick-change female connector. This makes the system better suited to the trend of multi-variety, small-batch production.