In automated screw-assembly lines, the single-cycle time required to deliver a screw to the driver directly determines the overall production takt.

Especially in high-throughput situations, shaving off just a few milliseconds per cycle yields a noticeable efficiency gain.

This paper presents two collaboration-based improvements—one for long-distance feeding and one for small length-diameter-ratio screws—that shorten the cycle by overlapping storage and motion operations, raising the speed of the whole automated line without major re-engineering.

1. Understand the ordinary linear sequence

A conventional “driver-feeder tube-driver module” line executes the following five steps in strict order:

Feeder supplies the next screw

Screw travels through the feed tube

Module drives and tightens the screw

Module retracts and resets

Module moves to the next hole

If the next screw is not blown toward the nose until Step 4/5 is finished, the tube transit time becomes pure waiting, and the waste grows with distance.

Breaking this linear limitation is the key to a faster cycle.

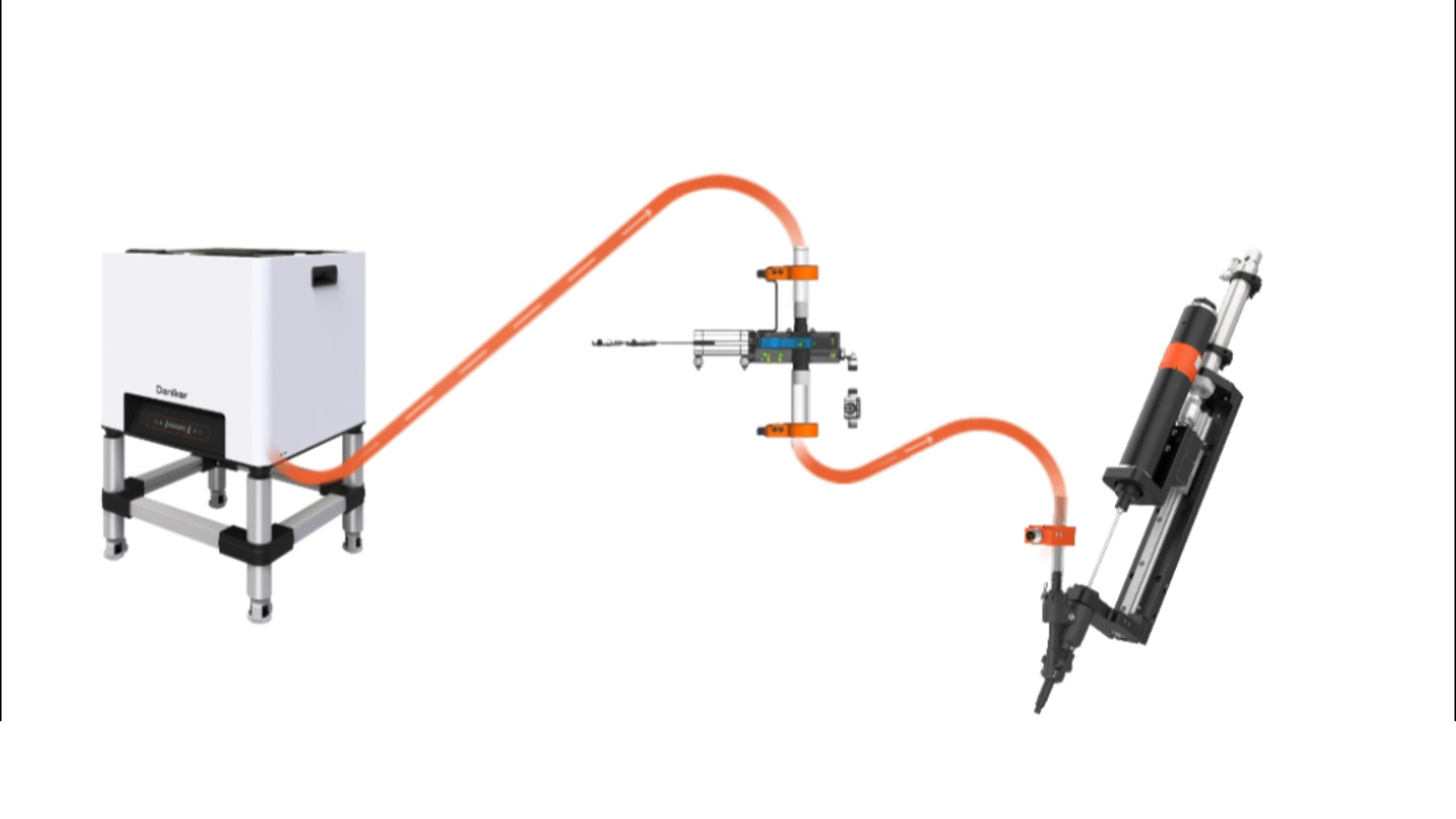

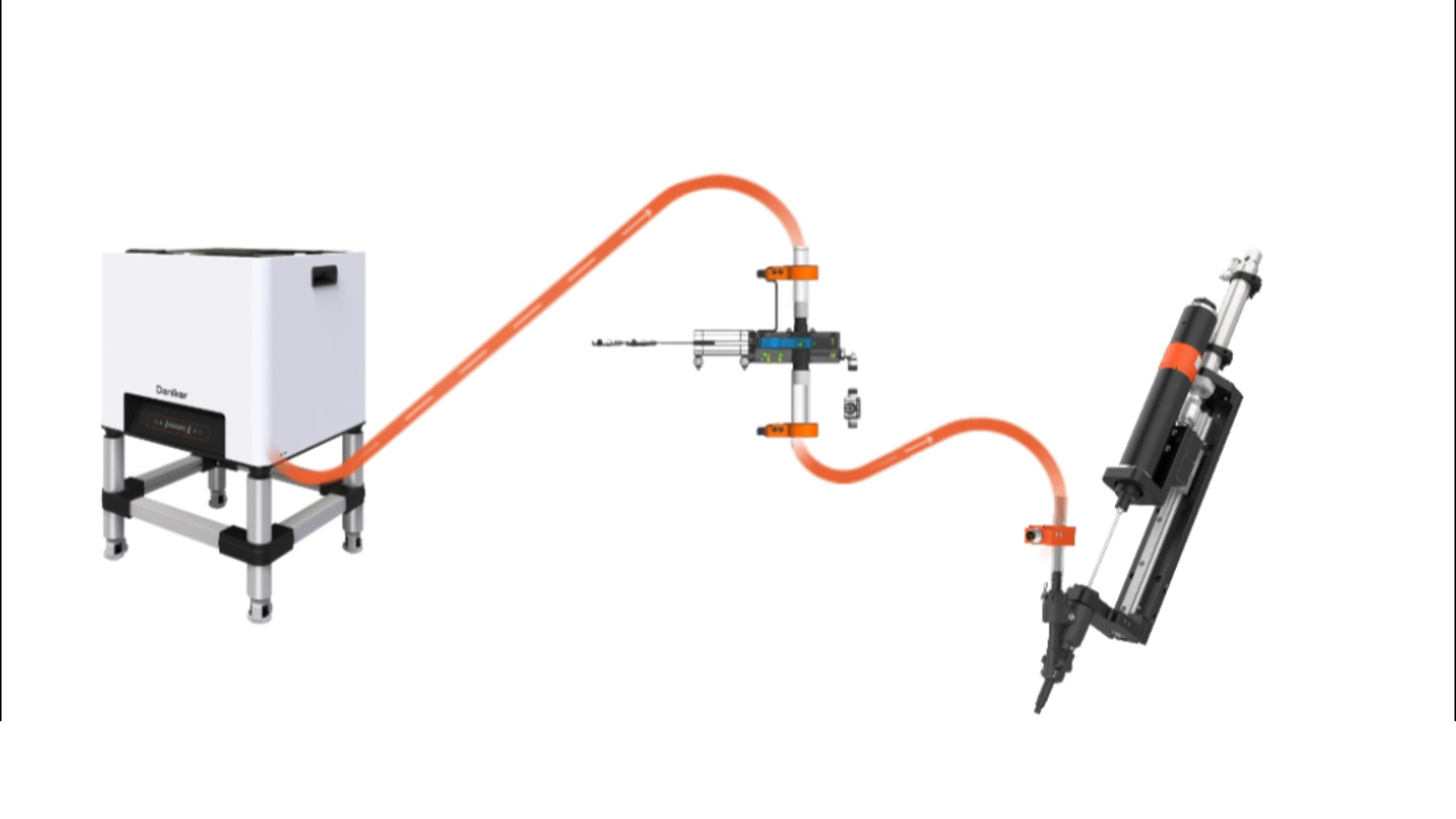

2. Long-distance feeding: add a local buffer module

Idea

Insert a small “magazine/buffer” right beside the driver module, forming a two-stage path:

Feeder → Buffer → Driver nose

While the module is still travelling, the next screw is already waiting in the buffer; only the last few centimetres have to be covered after arrival.

Sequence with overlap

Module finishes current screw

During tightening, feeder blows the next screw to the buffer (parallel operation)

Module retracts and indexes to the next hole

While moving, buffer blows (or blow-and-vacuum) the pre-stored screw into the nose

Module arrives with screw already in place; driving starts instantly

Result

Shortened blow distance (last centimetres only)

Transit time hidden inside robot motion

No change to feeder or PLC hardware—only timing and a low-cost buffer are added

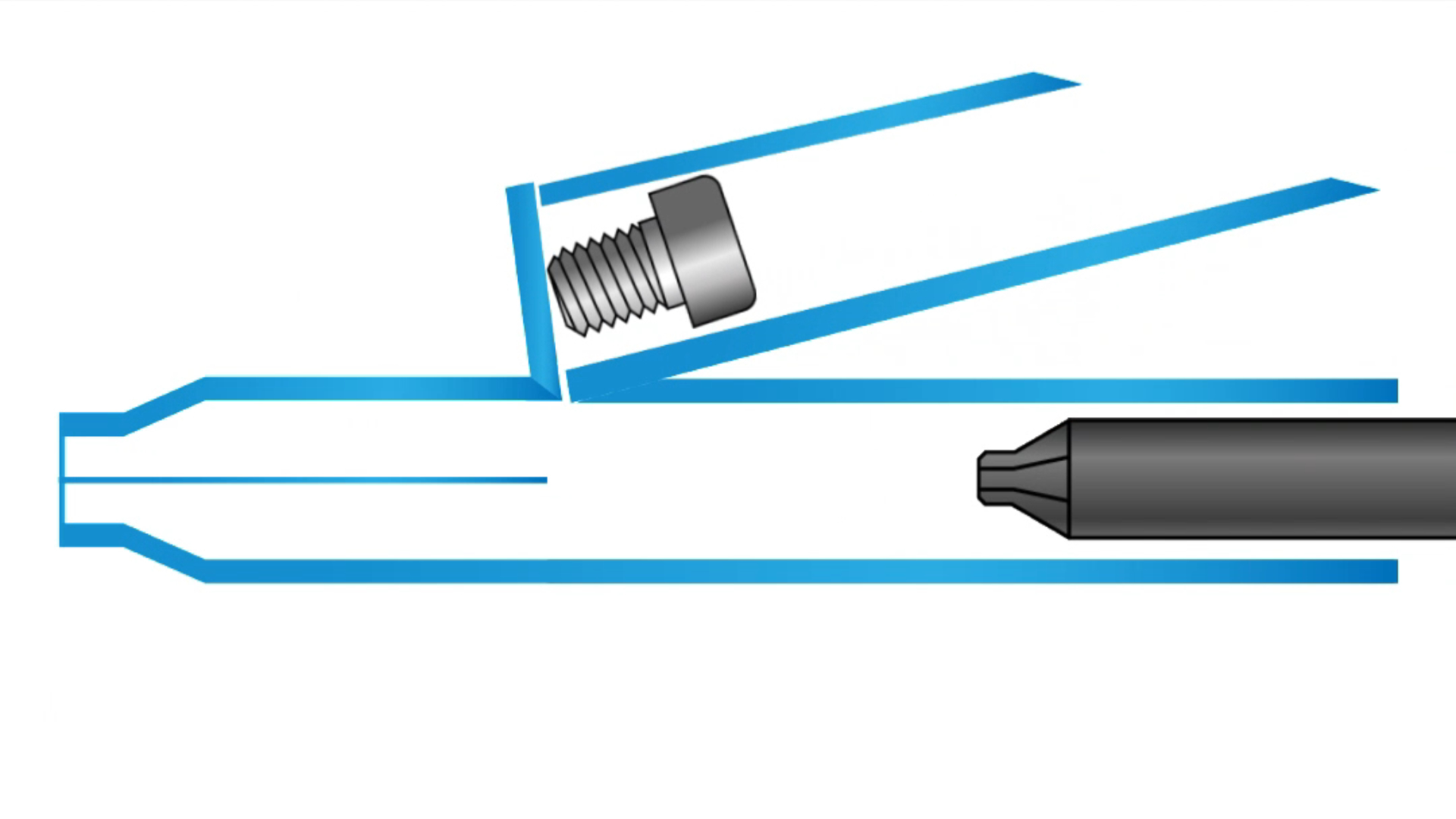

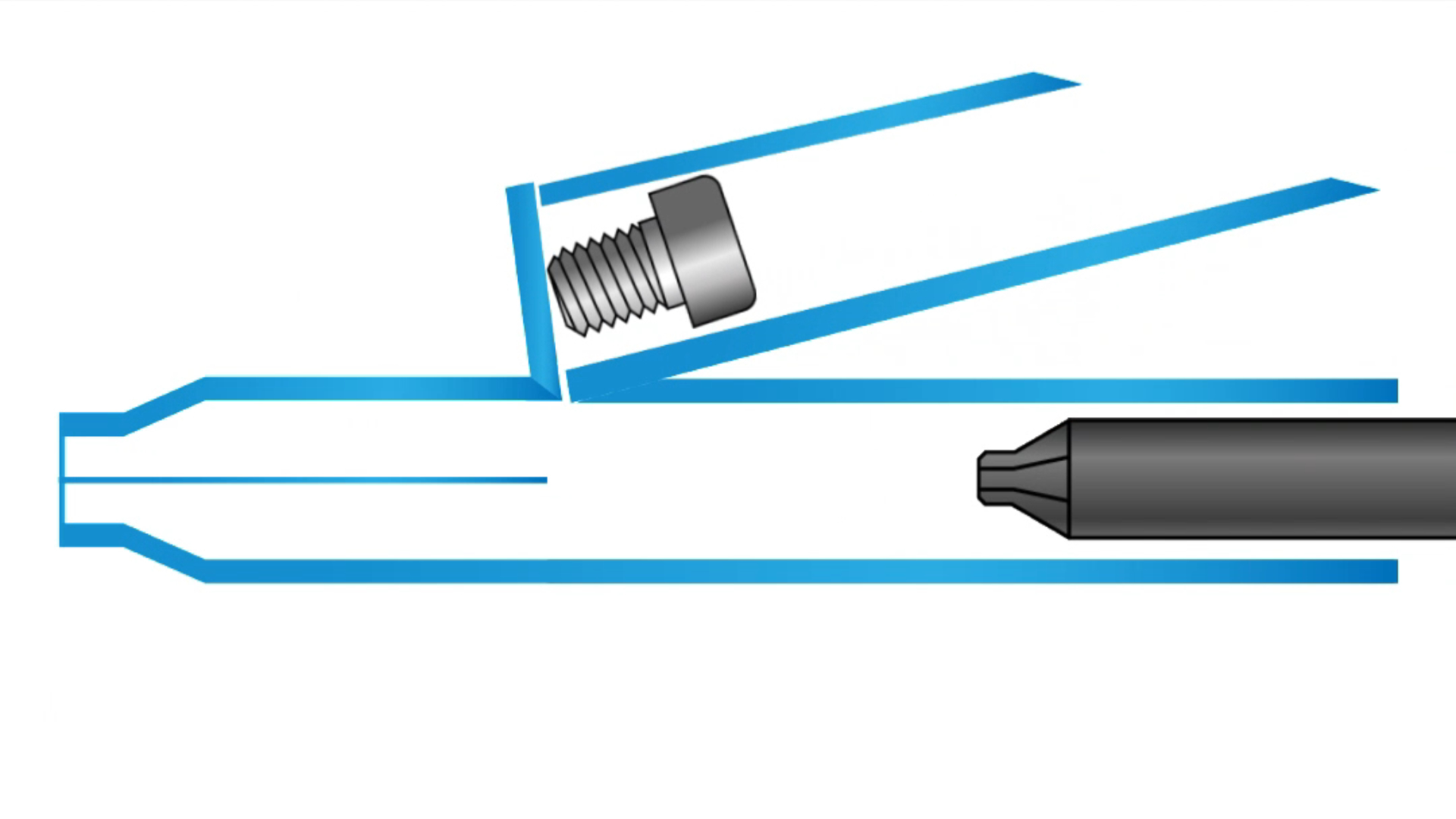

3. Small length-diameter-ratio screws: swing-arm driver with built-in buffer

Problem

Screws with L/D < 1.6 tend to flip in the three-way nose and jam.

Solution

Use a swing-arm driver whose feed channel can pivot.

The arm itself acts as an internal magazine.

Overlapped sequence

Module tightens current screw

During tightening, feeder blows the next screw into the swing arm (pre-store)

Module retracts; gravity drops the pre-stored screw straight into the nose

Module moves to next hole and drives immediately

Benefits

No external buffer—compact and inexpensive

Flipping eliminated because the screw is captured inside the pivoting channel

Same parallel timing as the long-distance version

4. Implementation notes

Both schemes keep existing feeders, tubes and robots; only a low-cost buffer or swing-arm nose is bolted on

PLC program is updated to overlap the “feed-next-screw” command with the previous “tighten & move” window

Cycle-time reduction is achieved without sacrificing feeding reliability

By replacing the traditional linear flow with “store-while-you-work” collaboration, manufacturers can compress takt time and boost line capacity at minimal expense and risk.