In the process of automotive seat assembly, a mature and reliable bolt-tightening technology solution can reduce defects and errors during production, ensure the quality and reliability of seat bolt tightening, and significantly reduce accidents in later use. Improper tightening of seat bolts may cause the seat to suddenly shift forward, backward, or downward during braking, producing abnormal noises. In mild cases, this affects driver operation; in severe cases, it endangers the lives of all occupants. Therefore, it is essential to develop targeted process research and identify an economical and reliable intelligent tightening solution for automotive seat bolts.

Wuxi Danikor, as a high-tech enterprise in the field of automation, has proposed an intelligent tightening solution for automotive seat bolts, which has been adopted by several well-known automotive seat manufacturers. The solution significantly reduces operator workload, improves efficiency, ensures tightening consistency, enhances product quality, and safeguards driver safety.

In addition to automatically determining whether the tightening result is OK/NG, Danikor’s intelligent tightening system can also provide the type and reason for NG results, and interact with operators through sound and light alarms. By leveraging computer technology, every tightened screw is recorded, making the quality of each product traceable and enabling data-driven tightening quality management.

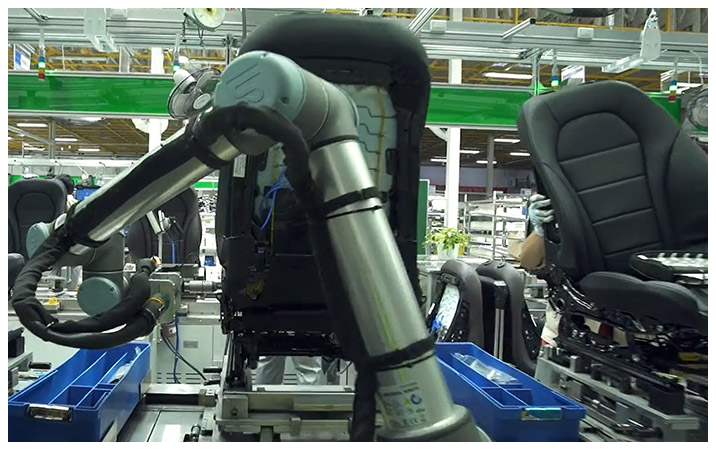

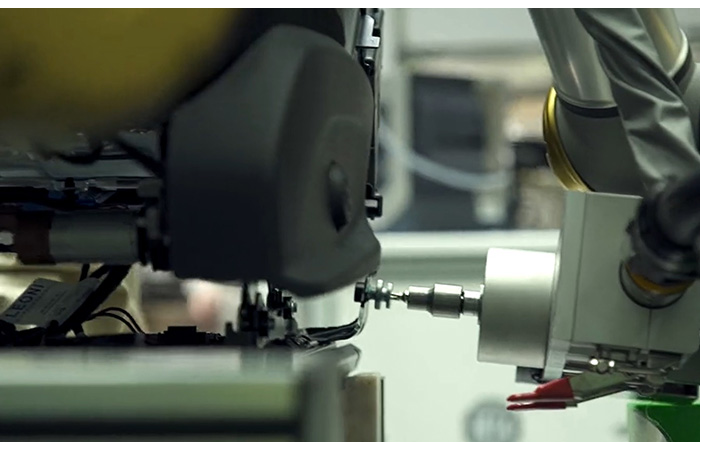

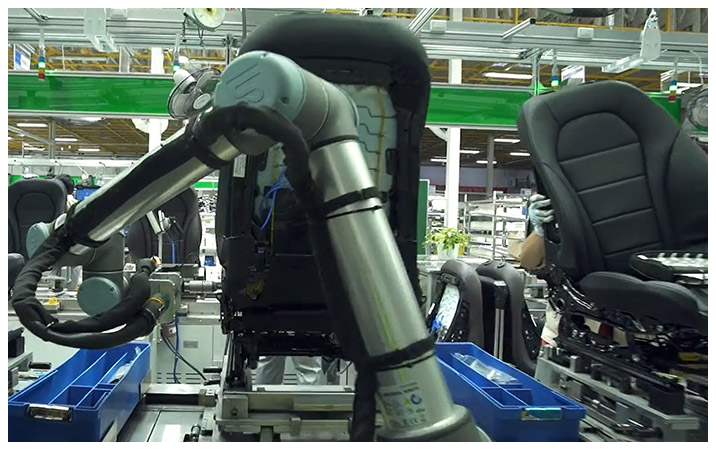

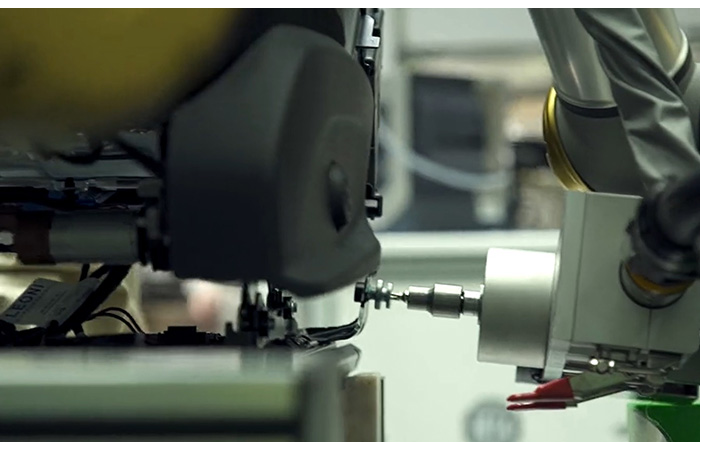

A globally renowned automotive seat manufacturer has also optimized its seat assembly process by introducing Danikor’s intelligent tightening solution. On this production line, the Danikor system completes approximately 8,500 tightening operations per day. Each seat is equipped with a transponder containing individual identification data. Once the seat reaches the tightening station, the transponder is read, and the intelligent electric screwdriver tightens several screws on both sides of the seat. If any screw is missing, the system will reject the product and issue a warning. Since each step is carried out sequentially on the conveyor, the intelligent tightening system can work alongside operators in limited space, while digital monitoring prevents defective seats from continuing down the line. This not only improves production efficiency but also further ensures product reliability. Additionally, Danikor’s intuitive user interface allows for simple programming and setup—any operator can complete tasks through manual teaching.

The solution includes an intelligent electric screwdriver, tool controller, software system, industrial PC, and scanning devices, forming a complete intelligent tightening system. The electric screwdriver is equipped with Danikor’s high-precision torque control algorithm, with torque accuracy within ±7.5%. Parameters are adjustable, and tightening records can be saved, exported, and uploaded to the MES system for full traceability. Core components are imported to ensure quality, longevity, and stability. The tool controller features a visual interface and multimedia technology, allowing operators to instantly understand system status and results through sound and light indicators. The system is modular in hardware and foolproof in design, with simple software and easy operation.

Danikor Intelligent Tightening System – Error-Proofing Design

Common bolt tightening failures in product assembly include:

Missed Operations – Operators may not know whether the current product has been completed after a break or shift change.

Incorrect Number of Tightenings – Due to continuous 24-hour production, fatigue can lead to missed tightenings.

Incorrect Tightening Sequence – When multiple bolts are involved, the sequence is specified in the work instructions. Fatigue or frequent operations can lead to sequence errors.

Premature Trigger Release – Operators may accidentally release the tool trigger before reaching the target torque.

Bolt Misalignment – Due to space constraints or manual error, bolts may be tightened at an angle, appearing to reach torque but not fully seated, leading to functional failure.

Danikor’s intelligent tightening system addresses these issues with position-based error-proofing control.

Equipment Communication

The MES (Manufacturing Execution System) is a comprehensive information system for factory-level production management. It handles product data statistics, production planning, and traceability. In this solution, barcode scanning is used to call up the appropriate tightening program from the MES system. The required torque (pre-configured in the electric screwdriver according to national standards and customer approval) is applied. After tightening, the result is sent to the PC, printed as a 1D or 2D code, and affixed to the product for full traceability.

Fixtures are equipped with limit switch sensors for error reporting, and inductive sensors prevent missing parts. Every tightening operation is recorded for traceability. Danikor’s position and sequence error-proofing system ensures correct location, quantity, and torque for both vertical and horizontal tightening operations. The system integrates with MES and PLC via Ethernet, and interlocks with the production line through I/O hardwiring.

Danikor Automotive Seat Bolt Intelligent Tightening Process

The seat is transported to the tightening station.

The system determines whether tightening is required. If not, the seat proceeds.

If tightening is needed, a barcode (or RFID) is scanned to retrieve seat processing info.

The system selects the appropriate program based on the seat’s processing history.

Tightening is performed, and the system checks whether to switch to the next point.

After completion, the system returns to the initial position and checks if the operation is qualified.

If unqualified, the product is sent for rework; if qualified, it proceeds down the line.

Conclusion

Tightening solution validation is a critical part of process quality control. An unstable tightening process leads to inconsistent quality and unpredictable risks for end users. Torque control for automotive seat bolts is a systematic and complex task—an iterative process of practice → validation → adjustment → re-practice. Any “change point” in production can cause torque anomalies. Only through dynamic management can reliability be ensured when the vehicle is delivered to the customer.

Danikor’s intelligent tightening solution for automotive seat bolts can tighten screws at any angle, with torque up to 105 N·m, rich tightening strategies, foolproof design, and full data traceability. It is fully capable of handling automotive seat tightening applications, solving challenges such as narrow workspaces, interference, and compact stations.