How Flexible Feeders Solve the Five Major Drawbacks of Traditional Vibratory Feeders in Automated Feeding of Irregular Parts

In the automated production and assembly of various products, a feeding process is essential. However, since most product components are irregularly shaped, there is no standardized feeding method for such parts. Currently, most feeding processes rely on traditional vibratory feeders, but these present five major drawbacks when handling irregular parts in automated feeding systems:

Large Footprint

The top bowl of a traditional vibratory feeder typically ranges from 80mm to 1000mm in diameter. The size of the irregular part determines the size of the feeder; the larger the part, the larger the feeder, and thus the more space it occupies. Additionally, the more discharge rows required, the larger the feeder diameter becomes.

High Vibration Levels

The weight of the irregular part determines the vibration frequency. Heavier parts require higher frequencies, leading to greater stress and strain rates, as well as increased noise. This makes it difficult to meet the requirements of stress ≤450µε and strain rate ≤20K/s (as per IPC/JEDEC-9704A standard). While stacked structures can reduce the space occupied by the feeder, they concentrate the vibration source, causing interference between layers and increasing the overall weight of the feeder.

Lack of Versatility

The circular track and linear vibration conveyor of a traditional feeder are custom-designed based on the specific characteristics of the parts. Since each part has unique features, traditional feeders lack universality. When switching between different irregular parts, the feeder must often be replaced. Due to the non-contact interface between the circular track outlet and the linear conveyor inlet, alignment is challenging and time-consuming. The stability of the feeder relies solely on its own weight, making it susceptible to displacement from external forces. Moreover, since both the feeder and conveyor vibrate at different frequencies and amplitudes, misalignment can occur during operation, requiring frequent adjustments. Multi-row or multi-layer feeders are even more cumbersome to replace, adjust, and stabilize. As a result, traditional feeders cannot complete product changeovers within 4 hours, limiting their applicability in small-batch, multi-variety production environments.

Magnetic Interference

Most traditional feeders use electromagnetic vibration. However, for parts that require strict magnetic control—such as magnet rings that need to be magnetized after injection molding—traditional feeders are unsuitable due to the risk of premature magnetization.

Risk of Part Damage

In industries like automotive, watchmaking, and electronics, many irregular parts have surfaces prone to scratching. During the cyclic feeding process in traditional feeders, parts can be damaged by contact with each other or with the feeder tracks. Continuous vibration and friction can also degrade the appearance of the parts.

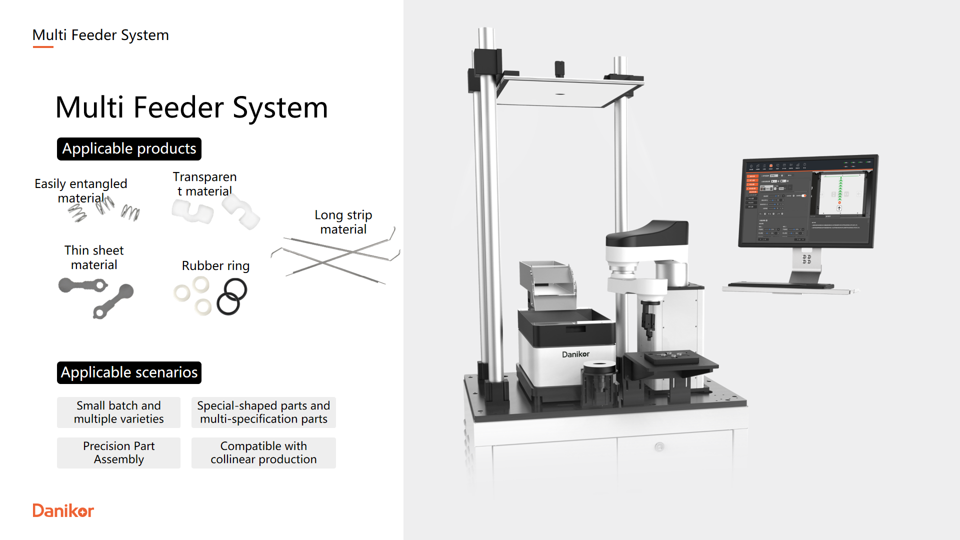

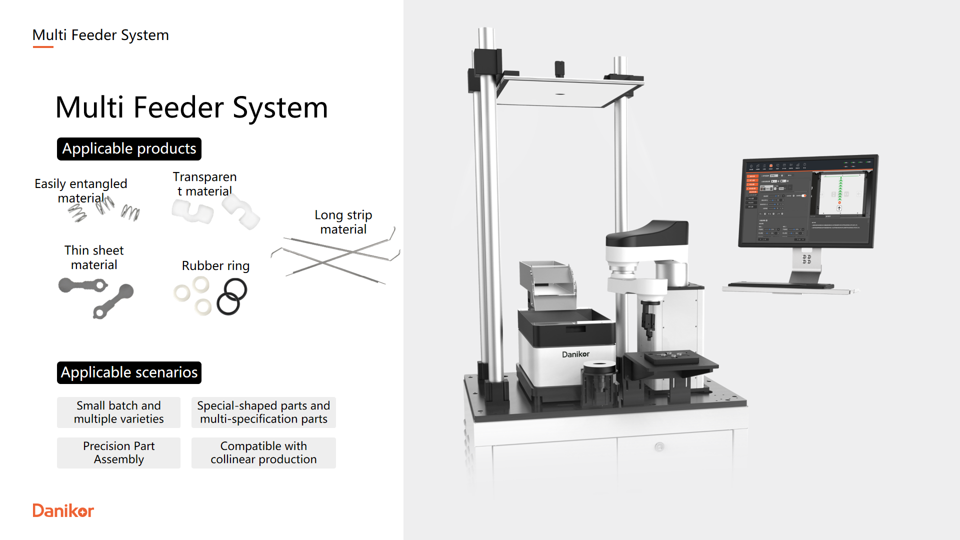

Danikor’s Flexible Vibratory Feeder is a highly versatile feeding device that effectively solves the challenges of feeding irregular parts through integration with a DK vision positioning system and robotic control. Danikor offers seven models of flexible feeders, suitable for irregular parts ranging from 0 to 120mm in size. These feeders use motor control technology to independently manage four motors, enabling seven different motion modes that can be freely combined. The system includes a built-in control unit, compact footprint, and quick-release trays for easy installation and operation. With stronger amplitude and better motion performance, the vision system automatically detects material shortages and guides robotic picking. Vision parameters can be set in as little as 10 seconds, and real-time imaging identifies part position and orientation, enabling fully automated flexible feeding.

Flexible vibratory feeders meet the demands of modern automated production for multi-variety, small-batch manufacturing by enabling quick changeovers, ensuring feeding efficiency, reducing labor costs, and improving overall productivity—delivering multiple benefits in one solution.