Commonly used tightening processes include the torque method, torque-angle method, and slope method.

1. Torque Method

The torque method is a straightforward process that controls tightening by torque alone, based on the fundamental formula T = k·D·F. This method only requires standard tightening tools. However, since it lacks angle monitoring, it cannot easily detect anomalies such as "false torque" during tightening. Therefore, it is typically suitable only for ordinary bolts of grade 10.9 and below, which have relatively high stiffness. When using the torque method, the bolt stress level must be kept within the elastic deformation range.

2. Torque-Angle Method

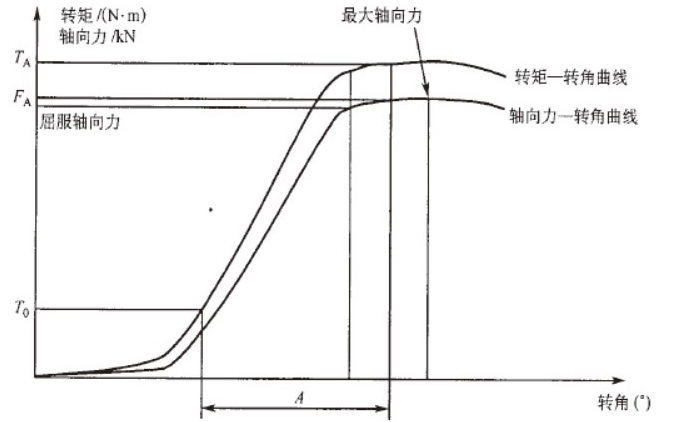

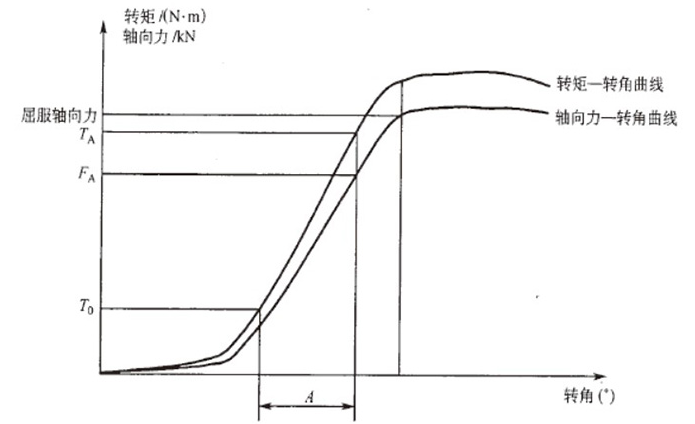

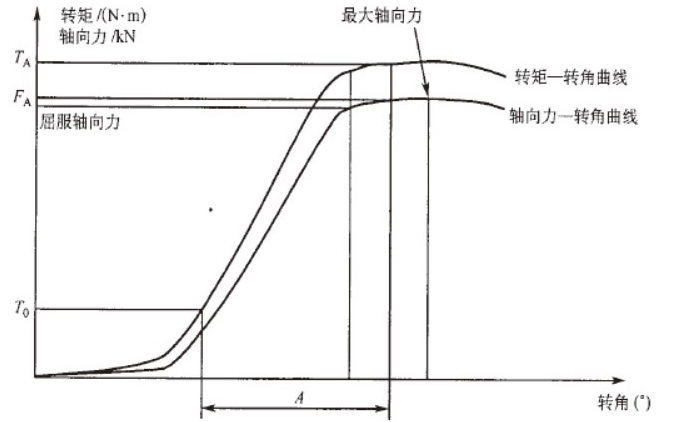

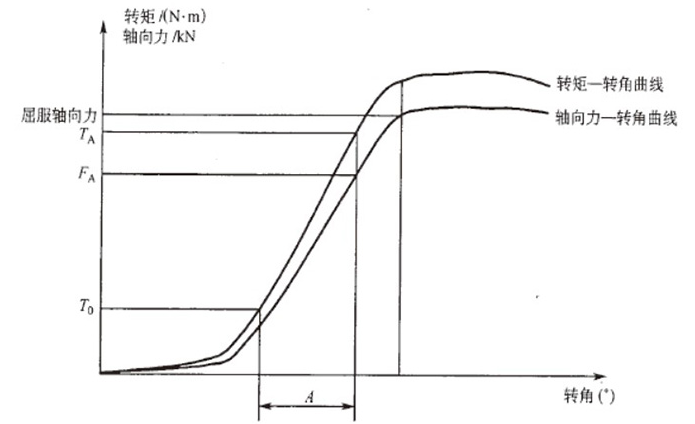

The torque-angle method first tightens the bolt to a seating torque (T) and then rotates it by a specific angle (A)—typically a multiple of 60° or 90° for manual ease—to control the total bolt elongation and thus precisely regulate axial force. Unlike the torque method, the process parameters for torque-angle tightening can only be determined through specialized testing, not by calculation or reference tables.

This method requires expensive electric screwdriver with torque/angle control and monitoring capabilities, along with pre-development testing equipment. These tools not only control the tightening process but also monitor the final tightening state, detecting anomalies such as thread interference, seizing, excessive or insufficient strength, abnormal deformation, or fracture, and issuing warning signals for full quality assurance.

Due to its high technical and cost requirements, the torque-angle method is generally used for critical high-strength bolts, such as engine connecting rod bolts. It can tighten bolts within either the elastic or plastic range, as illustrated in Figures 1 and 2.

3. Slope Method

The slope method is a more precise tightening control technique developed from the torque-angle method. It monitors the slope (torque rate) of the torque-angle curve during tightening. Tightening stops when the slope decreases to a certain threshold, indicating bolt material yielding, hence its alternative name: yield point control method. Compared to the torque-angle method, the slope method demands even higher equipment precision.

Historical & Application Context

The traditional tightening method is the torque method, while the torque-angle method emerged after 1960. Due to their differing principles of axial preload control, complexity, and precision, bolted joints can be categorized into:

In automotive applications, to balance reliability and cost-effectiveness:

Torque-angle tightening and grade 12.9 high-strength bolts are typically used for critical engine fasteners.

Torque-method tightening with grade 10.9 and below bolts is common for axles, transmissions, chassis, and body components.

Since automotive bolts are often used in groups, both torque and torque-angle methods are usually combined with stepped tightening or secondary tightening to ensure uniform axial preload across all bolts.

Danikor electric tightening tools fully meet current tightening control and monitoring requirements, enabling simultaneous group tightening of all cylinder head bolts in engines—ensuring assembly quality while significantly improving efficiency.

The evolution of threaded fastener tightening technology and the fasteners themselves is driven by the need for joint reliability and structural lightweighting, reflecting advancements in threaded joint design, process engineering, and material technology.

In practical applications, it is crucial to distinguish between design torque, actual tightening torque, and inspection torque, ensuring alignment among design, manufacturing, and quality control departments.